Experts in helping you source, produce, and receive the best in metal fabrication from Vietnam producers.

Partner with us to work with an American owned sourcing and production company with people on the ground to handle getting you the highest quality products.

Getting Started

First, we need to do a phone call to get an idea of what the item specifications are, how many you are looking for, and a target price. We will discuss production here in Vietnam and talk about previous manufacturing you have done in China or elsewhere. Once we move forward we help you with factory selection and manufacturing. Lastly we will work with you and our partner logistics company to ship your product via air or sea.

To get started fill out the simple form below and we will setup a time ASAP to speak with you.

No Fields Found.

We have a comprehensive manufacturing and supply chain solution that allows you to focus on other key business objectives. We identify offshore factories, work with them to design your product, negotiate prices and production schedules, manage production, conduct quality control inspections and arrange all shipping logistics. Fill out the form above and speak with us today.

.

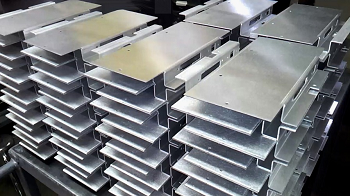

When we talk about metal fabrication, the one thing that came to our mind is welding. But the fact is, welding is just one process of metal fabrication. Fabricators use different other processes to fabricate the metal. In this article, you will read about metal fabrication in detail.

What is Metal Fabrication?

Metal fabrication is a process in which metal parts or products are made by cutting, bending, assembling processes. In metal fabrication, machines, parts, and structures are manufactured from raw material. There are a wide variety of techniques that are used to shape the metal into the machine or a part.

Material for Metal Fabrication

The customized metal fabricated products are made from a wide range of metals and their alloys. Some common custom metals available for metal fabrication are brass, gold, copper, iron, nickel, aluminum, magnesium, silver, tin, titanium, and other grades of steel.

How does metal fabrication work?

The Bidding

The metal fabrication job is based on bids. Metal fabricators bid on jobs by submitting their drawings, and if they won the project, they start working.

The Planning

Once the contract is awarded to fabricators, they started planning out the things to build this project. Planning includes ordering raw material for the project and hiring some other fabricators experienced in specific processes to create a final product.

Execution

After planning, it includes the implementation of the plan. It involves certain processes and professionals to build the product or product parts. It needs some use of tools and processes like cutting, folding, drawing, punching, welding, and some other procedures.

Process of Metal Fabrication

When a project is awarded, it involves some fabrication processes according to the need for the product’s intended purpose and its material. Not all, but some methods are used in metal fabrication, but every product demands different processes.

Here is a description of some standard custom processes of metal fabrication.

Casting

In this process, molten metal is poured or die and then allowed to cool and harden to get the desired shape. This process is suitable when there is a reuse of the same mold to create an identical product. Casting further has some other processes like die casting, mold casting, and sand casting.

Cutting

Cutting is the most crucial and common fabrication process in which a material is cut and split into different small parts. Sawing is an old method of cutting, and modern methods of cutting include laser cutting, power scissors, water-jet cutting, and plasma arc cutting.

Drawing

This process involves tensile force to pull the metal through a tapered die. The die stretches the metal into thinner shape. The drawing process is performed at room temperature and is called cold drawing.

Folding

Folding is often done with sheet metal fabrication and includes pressing the metal to bend it into a certain angle. Brake press is used to create creases in the metal by pinching it. The workpiece is placed between a punch and die and put pressure to crease from the pinch. Hammers are also used to fold metal.

Forging

In this process, the compressive force is applied to the metal to form a shape. A hammer or die strikes the metal until the desired shape is formed.

Extrusion

In this process, the workpiece is forced through or around an open or closed die to form a desired shape. Extrusion has a further two types: cold extrusion and hot extrusion.

Machining

In this process, metal is shaped by removing unwanted material from it. Machining includes different processes like drilling, turning, and milling.

Punching

In this process, holes are created in the metal shape by a punch pressing machine. The final product may need some assembling of other parts and requires some holes for fastening purpose.

Shearing

This process includes a straight cut and a division of metal into two or more parts. It is ideal for cutting smaller lengths and different shapes and involves only two tools.

Stamping

This process is similar to punching, but there is one difference between these two. Stamping includes pressing the metal, but the holes are not made on the metal. Stamping is used to form shapes, letters, or images on the metal sheet.

Welding

It is used to join two or more metal pieces with a combination of heat and pressure. This is a popular process, and it has further four popular types: Arc welding, MIG welding, TIG welding, and Flux Cored Arc welding.

–